A space for random thought

#4 Batteries (July 27th 2014)

I have a cordless drill of which the battery has died. I've tested it and it self-discharges from about 2Ah to nothing within a week. It uses 12 NiCd C cells. A friend of mine also has a battery which has died and uses 15 of the same cells. So i've bought a bunch of these (with tabs on) from ebay and have replaced the cells in both battery packs.

After carefully unpacking the cells, folding and soldering the tabs. Then squeezing it back into the casing. The last bit was the hardest part. It all seems to work.

Andrew here's that picure of your battery before surgery

Update Dec 3rd 2014

The batteries (both mine and Andrew's) are both holding up nicely - so far so good.

#3 Current measurement (September 8th, 2013)

In the process of making the spot-welder I wanted to know how much current is flowing in the secondary of my spot-welder. I put one of the secondaries through a ferrite core with a bunch of turns on it, however while there was plenty of signal it looks like it's saturating (badly) but then i guess a few hundred amps would do that. But on the bright side it's delivering a few hundred amps...

Rogowski coils don't saturate (air cored) and will be linear all the way up to the currents i need. So I stripped the screen off some coax, attached some kynar to it and wound a lot (100?) turns on it before connecting it to the core, heatshrink followes and a Rogowski coil is made. But of course they are differential sensors so one integrator (and a preamp) later i'm in the 1V/1000A (yes 1000A) territory and i'm seeing 1.4KA on the secondary of my spot-welder (calibration is difficult so it might be closer to 1KA). I'm quite pleased.

It wasn't very scientific and but it gives great results; i think i should make some more of these for different ranges.

#2 The need for a spot welder (September 8th, 2013)

How to make a spot-welder in a few hours from things you probably have lying around the house... How true this may be for anyone else i have no idea, but anyway. I need a spot welder for the (seemingly trivial task) of welding a handle back onto a pan lid.

I have a couple of large ~500VA mains to dual 48V torroidal transformers, i know that these will tolerate an overload by a factor of a few for a short time. I stripped off the windings of both the secondaries and re-wound 4 turns (1V/turn) of thick - really thick cable (2off 10mm square). Let's say 10A in 240V, i should get 500+ Amps output - enough for an OK spotwelder. That's an overload of a factor of 5, but as toroidal transformers will take a factor of 10ish when turned on i figure this will be OK provided i keep the duty cycle down.

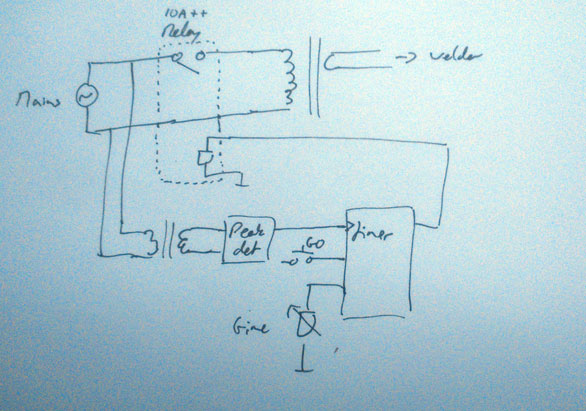

I built a trigger circuit based on a couple of 555s which switches in a relay on the high side of the transformer. One 555 gives a delay before closing the relay and the other 555 gives a configurable on time. The gotcha here was the inrush current when the AC input is close to zero, as there is no flux in the core this is large >16A (and kept tripping my breakers). So with a small transformer the first timer is triggered on the peak of the AC reducing the maximum current through the transformer due to the inductance. A block diagram is below

Block diagram of welder control circuit

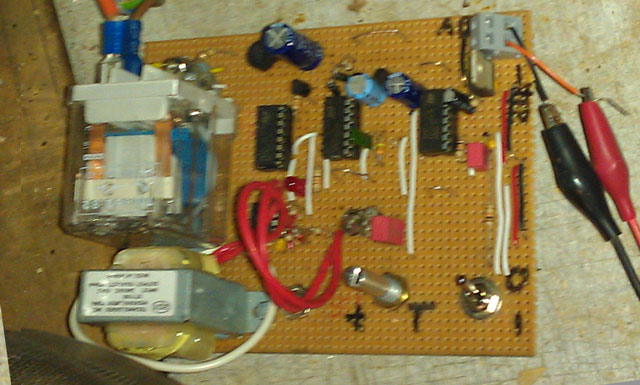

The actual circuit looks like this - although the photo isn't great

Circuit photo

Results

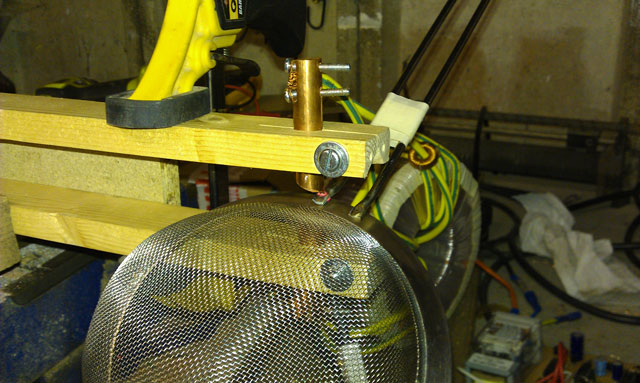

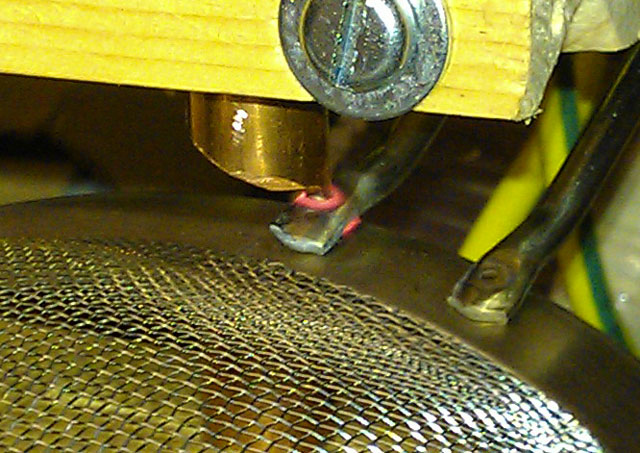

The spot welder works, and with a time of around a second welded my pan lid very nicely, it's thin stainless which is almost ideal for this sort of welding. A friend also needed a welder (and didn't fancy making one) and has a camera so here are some pictures of welding his sieve.

Welding Andrew's sieve

Close-up

All credit to Andrew for getting that picture, actually showing the weld! The welding time taken here is around 6 seconds. The force was applied with a clamp which can be seen in the first photo. The electrodes I used are a piece of round copper bar which i filed into some tips about 1.5-2mm diameter.

Update Dec 2014

Well both the pan lid and the sieve are still welded securely. I guess this was a success.

#1

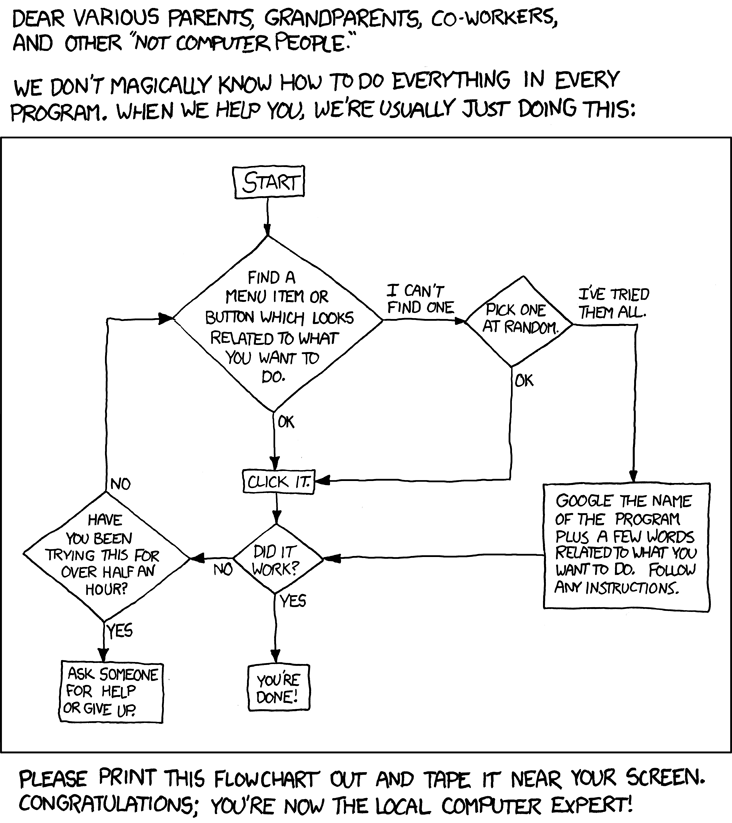

At the moment i haven't any. so have someone else's

it's from www.xkcd.com if you don't already read it you should. Hey why am i telling you what you should/should not do? Who am i to do this, your mother? Hmm, i should rephrase that, 'i really enjoy it, maybe you will too'. Anyway i guess that's random musings #1

Latest news

Study finished

Feb 8 2015

The study's now finished too. Next job Bethea's room.

Kitchen is finished (honest...)

Jan 10 2015

Skirting, architrave all done. Needs some paint here and there and the chandelier thing needs making but anyway - on to the study.

Kitchen is finished

Dec 3 2014

The kitchen has been defined as finished... Back to work this week.

Extension has started

Sept 15 2014

The extension has started, more soon.